Introduction

In today’s fast-paced manufacturing landscape, achieving precision and efficiency in CNC machining is crucial. Whether you’re a seasoned engineer or just starting out, this comprehensive guide to cnc machines will equip you with valuable insights to optimize your work. We’ll focus specifically on the CXC3 and CXC4 CNC machines from Akriti Precision Systems in Bangalore.

Understanding CNC Machine Precision

CNC machine precision refers to the ability of computer numerical control (CNC) machines to consistently produce accurate and reliable results. Tight tolerances and precise measurements are essential for tasks like milling, drilling, and cutting. Akriti Precision Systems, a leading manufacturer, specializes in high-precision CNC machines, including the CXC3 and CXC4 models.

The Role of Precision in Performance Optimization

Precision directly impacts overall CNC machine performance. When components are manufactured with high precision, they fit seamlessly, resulting in smoother operation and reduced wear and tear. This translates to increased productivity and minimized downtime. Akriti’s commitment to accuracy ensures that their CNC machines deliver exceptional results, even in complex machining tasks.

Key Factors Affecting CNC Machine Precision

Several factors influence CNC machine precision:

- Machine Rigidity: Sturdy construction minimizes vibrations and ensures consistent accuracy.

- Tool Selection and Maintenance: High-quality tooling enhances precision and extends tool life.

- Feed Rates and Spindle Speeds: Optimizing these parameters prevents tool deflection and improves surface finish.

- Software Capabilities: Advanced CAM software and precise G-code programming contribute to precision.

- Material Handling and Workpiece Setup: Proper alignment and fixturing are critical.

- Regular Maintenance: Keeping the machine in top condition maintains accuracy.

- Employee Training: Skilled operators enhance precision.

- Data-Driven Monitoring: Real-time monitoring helps identify deviations.

- Lean Manufacturing Principles: Streamlined processes lead to better precision.

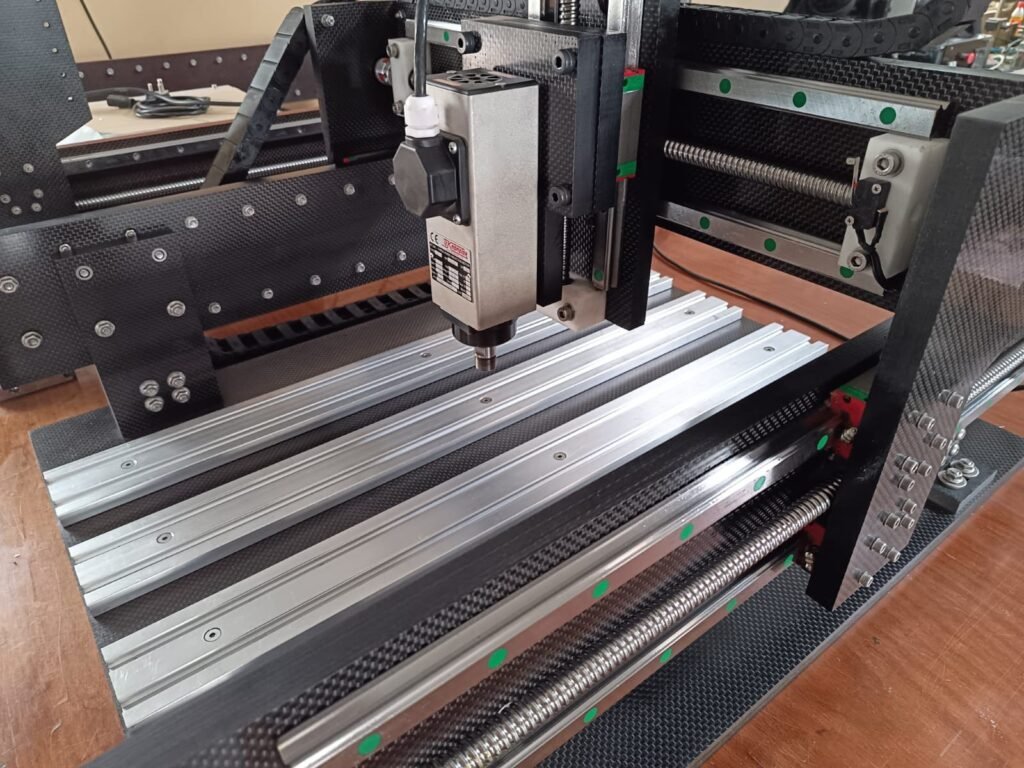

Akriti’s CXC3 and CXC4 CNC Machines

Let’s dive into the specifics of Akriti’s CXC3 and CXC4 CNC machines:

CXC3 CNC Machine

- Application: Ideal for precision milling and drilling tasks.

- Features:

- High-speed spindle for efficient material removal.

- Robust construction for stability.

- Advanced control system for precise movements.

- Use Cases: Aerospace components, medical devices, and automotive parts.

CXC4 CNC Machine

- Application: Suited for complex machining operations.

- Features:

- Multi-axis capability for intricate geometries.

- Automatic tool changers for uninterrupted production.

- High-resolution feedback systems for accuracy.

- Use Cases: Mold making, prototyping, and precision engineering.

Conclusion

I hope this comprehensive guide to cnc machines was helpful. By understanding CNC machine precision and leveraging Akriti’s CXC3 and CXC4 models, you can maximize efficiency and achieve outstanding results in your machining endeavors. Remember, precision isn’t just a goal—it’s the path to excellence in manufacturing.